In an era defined by technological innovation, the University of Birmingham is making waves with the launch of EvoPhase, an AI-powered design approach aimed at optimizing industrial processing equipment. EvoPhase promises to redefine the way equipment, including mixers, dryers, roasters, and blenders, is designed for processing granular materials, which constitute a significant portion of the world’s products and processes. This groundbreaking technology holds the potential to revolutionize industrial processes, improve efficiency, and deliver substantial cost and energy savings across various industries.

The challenge of granular materials

Granular materials, encompassing everything from fine powders in the food and pharmaceutical industries to coarse aggregates used in construction, are a fundamental component of numerous industrial processes. However, understanding and modeling the behavior of granular materials have posed significant challenges. Unlike fluids or gases, which are more amenable to computational fluid dynamics (CFD) modeling, granular materials consist of solid particles that can flow like liquids. This complex behavior makes mathematical modeling a formidable task.

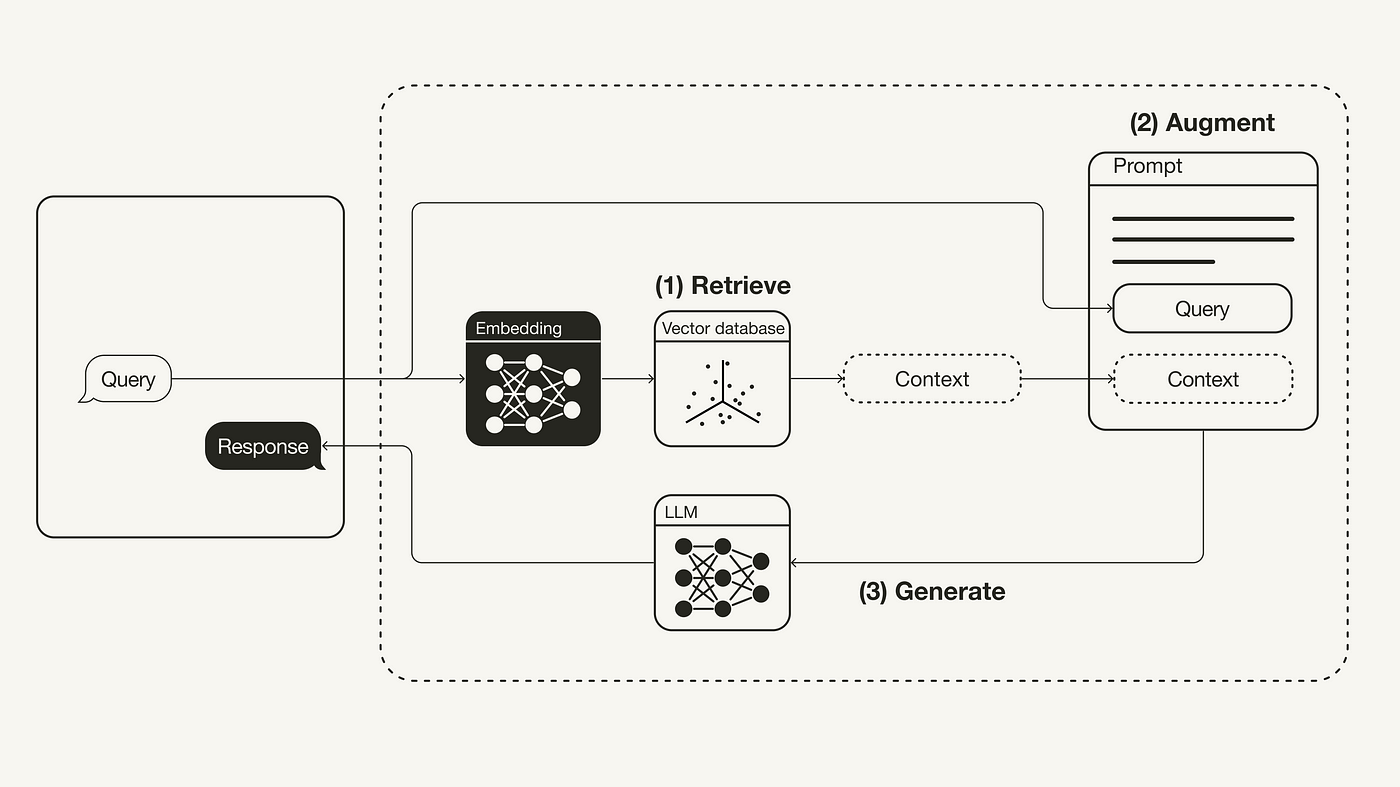

EvoPhase: The AI-powered solution

EvoPhase introduces a novel AI technology known as Highly Autonomous Rapid Prototyping for Particulate Processes (HARPPP). Operating akin to natural selection, HARPPP evaluates and tests various equipment designs to identify the optimal one. Users can define multiple parameters for optimization, such as power draw, throughput, and mixing rate. What sets EvoPhase apart is its ability to allow the evolving design to select the best combination of parameters, rather than forcing trade-offs between these targets.

Additionally, EvoPhase employs a numerical method called Discrete Element Method (DEM) to predict the behavior of granular materials by calculating the movement of individual particles. This sophisticated approach ensures accurate modeling of granular material behavior.

To further validate these calculations, EvoPhase utilizes Positron Emission Particle Tracking (PEPT), a technique developed at the University of Birmingham. PEPT is a variant of positron emission tomography (PET), a medical imaging technique used in nuclear medicine. By leveraging PEPT, EvoPhase ensures the precision and reliability of its predictions.

The innovators behind EvoPhase

EvoPhase is the brainchild of a team of visionary researchers from the University of Birmingham’s School of Chemical Engineering. The team includes Dominik Werner, Leonard Nicusan, Jack Sykes, and Kit Windows-Yule. With the support of the University of Birmingham Enterprise, a service dedicated to helping researchers transform their ideas into real-world solutions, products, and enterprises, EvoPhase has come to fruition.

A multifaceted solution

EvoPhase offers a multifaceted approach to address challenges that traditional research and development methods often struggle to overcome. It encompasses material characterization, digital model development, experimental imaging, process condition optimization, geometric design enhancement, scale-up, and predictive model development. EvoPhase’s versatility extends to designing equipment for processing powders, granules, and fluids across a wide range of industries.

Unlocking cost and energy savings

EvoPhase holds the promise of not only revolutionizing industrial equipment design but also delivering significant cost and energy savings for various industries. Leonard Nicusan, EvoPhase’s Chief Technology Officer, emphasizes that their technologies enable them to tackle assignments related to material characterization, digital modeling, process optimization, and more. The approach is poised to increase energy efficiency, enhance mixing effectiveness, and boost throughput, leading to substantial cost savings for industries.

The launch of EvoPhase by the University of Birmingham represents a significant stride in the field of industrial equipment design and optimization. By harnessing the power of AI, advanced numerical methods, and experimental validation, EvoPhase offers a holistic solution to the complexities of granular materials processing. With its potential to enhance efficiency and reduce costs across industries, EvoPhase serves as a testament to the transformative impact of innovative research and development in the modern era. As industries increasingly adopt EvoPhase, the world can anticipate a more efficient and sustainable future in the realm of industrial processing equipment.